High-Performance Anchor Systems for Any Kind Of Application

High-performance anchor systems are important in making certain safety and security and security across a plethora of applications, from construction to aerospace. Understanding the subtleties of different anchor types and their respective installment techniques is important.

Kinds Of Support Solutions

When thinking about the diverse applications of support systems, what are the primary kinds that specialists depend on for high-performance outcomes? Support systems can be extensively categorized into numerous types, each created to meet specific demands based upon the nature of the lots and ecological conditions.

The very first group is mechanical anchors, which include development anchors, wedge anchors, and screw anchors. These are normally employed in concrete and stonework applications, supplying durable holding power through mechanical interlock or rubbing.

Another significant kind is sticky supports, which make use of chemical bonding agents to safeguard the support within the substrate. This type is specifically useful in applications where high tensile strength and resistance to shear forces are required.

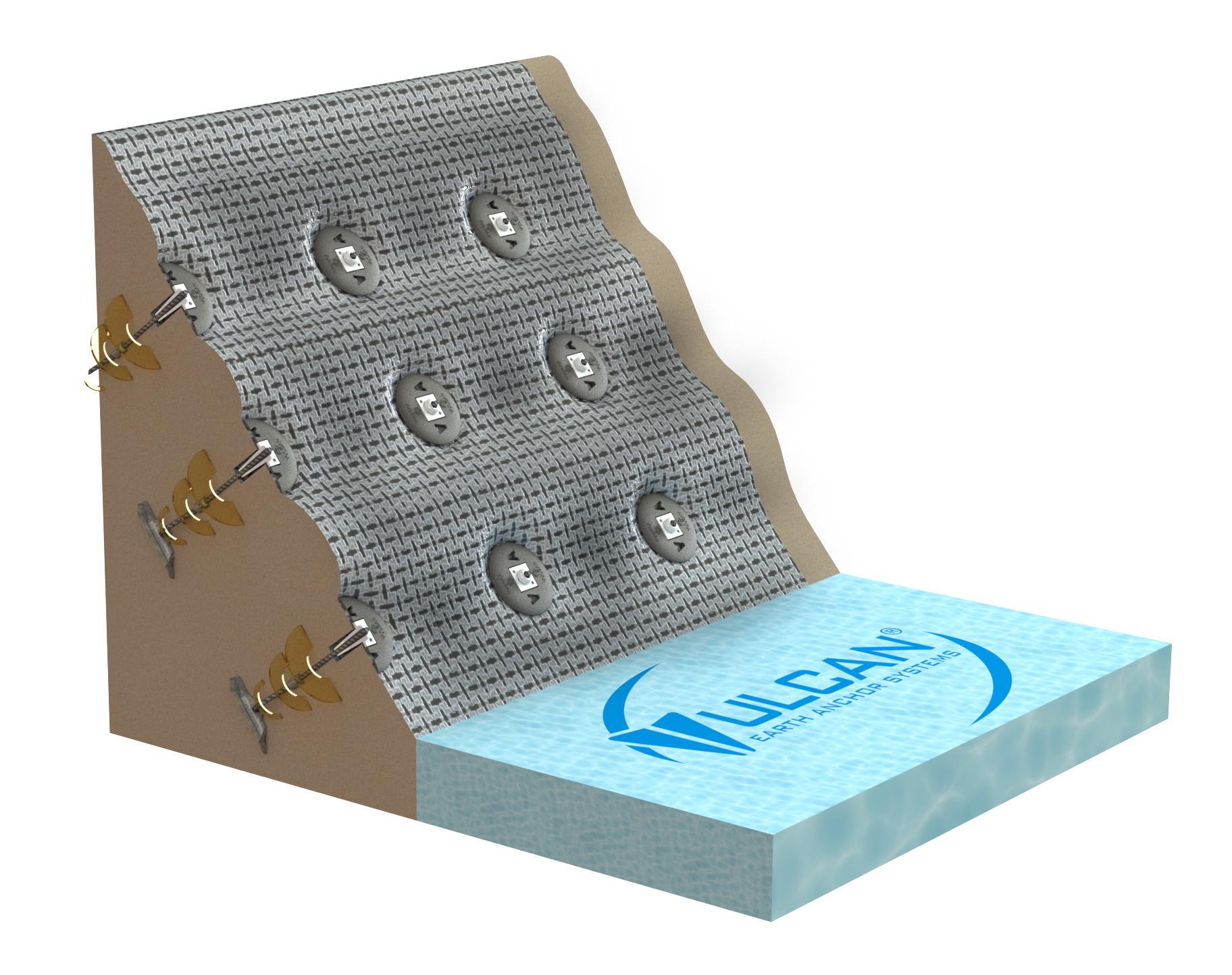

Furthermore, there are easy supports, such as deadman supports, which count on the weight and resistance of bordering products to secure objects. They are typically made use of in outside applications or where vibrant lots are present.

Lastly, there are specialized anchor systems like ground supports, which are made use of in civil design and building and construction projects for stabilizing frameworks. Each kind of support system is made with details efficiency metrics in mind, guaranteeing optimum safety and security and performance throughout different applications.

Secret Features and Benefits

High-performance support systems use an array of essential features and benefits that boost their performance in various applications. One of the main functions is their remarkable tons capability, which ensures stability and safety and security under considerable stress and anxiety problems. This is achieved via innovative materials and engineering layouts, permitting reputable performance in requiring atmospheres.

Furthermore, these systems frequently incorporate ingenious technology such as deterioration resistance and adaptability to various substrates. This not just extends their life expectancy yet likewise reduces maintenance expenses, making them an affordable solution in time. The versatility of high-performance support systems permits seamless combination right into various frameworks, improving their functionality throughout numerous projects.

One more remarkable advantage is ease of setup. Several high-performance anchors are made for quick and uncomplicated implementation, reducing labor time and boosting general task efficiency. Their light-weight nature facilitates transportation and handling, adding to streamlined operations.

Applications in Various Industries

In the transport industry, high-performance anchors are utilized to safeguard road and rail facilities, adding to the safety and security of passengers and lorries. Their reliability is vital in protecting against structural failures that might result in tragic accidents. In addition, in the sustainable power sector, these supports are crucial for protecting wind generators and photovoltaic panel installments, ensuring they endure ecological stress and anxieties while maximizing performance.

The aerospace sector also utilizes sophisticated securing solutions to secure components during manufacturing and transportation, where accuracy and integrity are crucial. In each of these applications, the option of ideal anchor systems can significantly impact overall task success, highlighting the adaptability and need of high-performance supports across numerous commercial landscapes.

Installation Techniques and Tips

Correct installation of high-performance support systems is vital to their performance and longevity. To make certain optimum performance, it is important to follow well-known installation methods customized to the particular sort of anchor system and application.

Begin by completely assessing the installment site, consisting of the substratum conditions, tons demands, and ecological factors. Exact dimensions and alignment are critical; use laser degrees or plumb lines to maintain accuracy. When boring, select the ideal little bit size and type for the anchor system, guaranteeing tidy and precise holes to stop material damages.

Make use of the recommended torque setups during securing to stay clear of under-tightening or over-tightening, which can endanger the support's stability. Additionally, adhere to the supplier's standards regarding spacing and edge ranges to optimize tons circulation and decrease potential failing points.

Always utilize individual safety tools (PPE) during the installment procedure, and take into consideration making use of specialized devices created for high-performance supports to improve efficiency and safety and security. Perform a thorough assessment post-installation to validate that all parts are securely attached and in positioning, making sure the support system is all set to carry out under expected tons.

Maintenance and Security Considerations

To make certain the durability and reliability of anchor systems, regular upkeep and security considerations have to be prioritized. Regular evaluations are crucial to determine damage, corrosion, or any architectural deficiencies that might compromise the anchor's efficiency. A comprehensive upkeep routine should consist of checking the stability of anchor components, such as welds, plates, and screws, and making certain that all links are protected.

In addition, environmental elements can considerably influence anchor systems. Direct exposure to harsh weather condition problems or corrosive compounds can speed up wear and tear. Using safety layers or making use of corrosion-resistant products can boost Visit Your URL toughness and lengthen solution life.

Security factors to consider are paramount; users should stick to producer guidelines pertaining to lots limitations and functional methods. Educating workers on correct use and possible risks is essential in stopping crashes. Applying a safety and security administration system that consists of routine drills and responses systems can grow a society of safety and security.

Conclusion

In final thought, high-performance support systems stand for a crucial technology throughout multiple markets, giving phenomenal load capability, deterioration resistance, and adaptability. Regular maintenance and complete inspections further enhance their performance, developing these anchor systems as crucial components in securing frameworks and equipment.

High-performance support systems are important in making sure safety and security across a multitude of applications, from construction to aerospace.High-performance support systems supply a variety of vital attributes and benefits that improve their performance in numerous check here applications. The convenience of high-performance anchor systems enables for smooth combination into numerous frameworks, enhancing their use across countless projects.

In diverse industries, why not try these out high-performance support systems play an important duty in guaranteeing architectural integrity and safety and security (Earth Anchor).In final thought, high-performance anchor systems stand for a vital development throughout numerous industries, giving phenomenal load capacity, rust resistance, and convenience